Thermal Fogging - efficient down to the last spot

The main fields of application are: Pest control, vector control, disinfection, stock and plant protection. Thermal Fog Generators produce a dense fog cloud which mixed with the appropriate active solution, produces an immediate effect on flying and crawling insects, as well as germs and bacteria are controlled reliably, both indoors and outdoors.

A brief explanation of the process

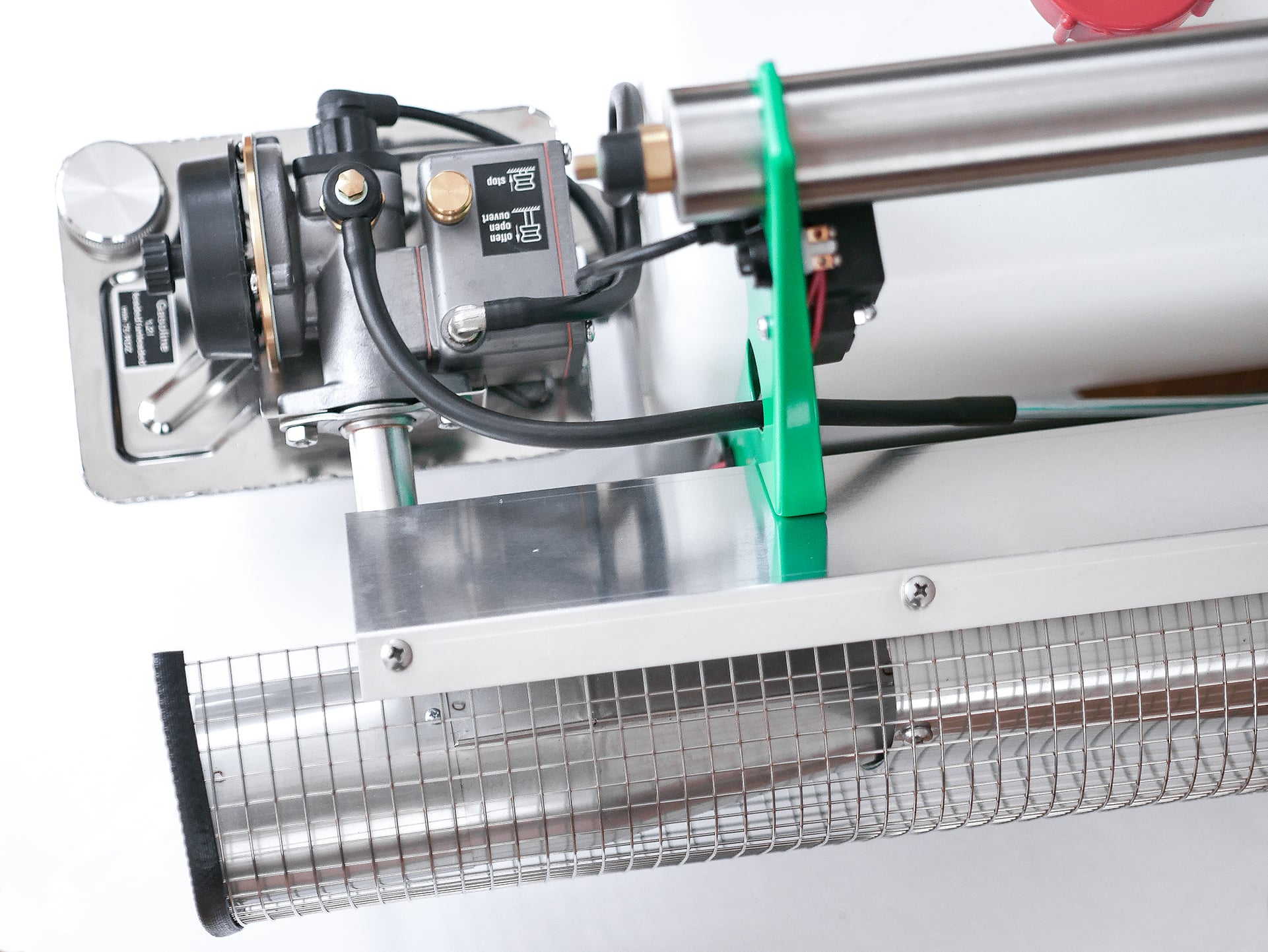

Each IGEBA thermal fogger consists of a carburetor, mixing tube, combustion chamber and expansion tube. The combustion of a gasoline-air mixture creates an oscillating gas column. At the open outlet of the expansion tube, the substance to be fogged is introduced into the pulsating, hot gas jet, so that a dense fog is produced. In suitable weather conditions, this thermal fog passes through an infested area in the open air in a very short time. Indoor areas are completely filled with fog. In the process, this penetrates into the last cracks and cavities.

Despite low application rates, an optimum efficiency of the applied agents is achieved. Both oil- and water-based agents can be applied.

- Droplet spectrum with oil-based carriers (e.g. diesel, kerosene)

< 20 micron (VMD)

- Droplet spectrum with water-based carriers

< 30 micron (VMD)

Advantages at a glance

- optimal droplet size < 20 micron (VMD)

confirmed by laser measurement - very high area coverage

- little or no carrier necessary

- excellent distribution in the room

- Fogging of water and oil based solutions

- high penetration depht

- low maintenance costs

- units with remote control for mounting on pick-up

Our Thermal Fog Generators